business field

A fan is an air machine that generates air volume and pressure by applying energy to air through the rotational motion of an impeller.

A unit with a pressure ratio between the inlet and outlet of less than 1.1 is generally classified as fan,

while a unit with a pressure ratio of 1.1 or more but less than 2.0 is generally referred to as “blower”.

Fans are classified as centrifugal and axial fans based on the direction of airflow and the angle formed by the impeller shaft.

They are further classified as follows based on the shape and structure of the impeller:

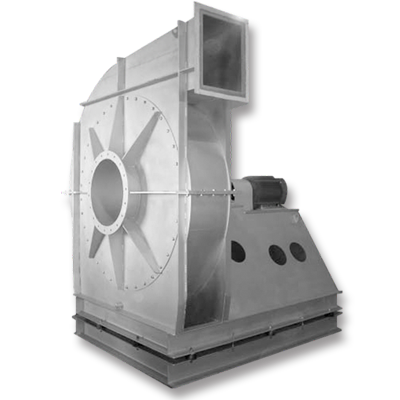

· Centrifugal Fans: Multi-blade Fans, Radial Fans, Backward Curved Fan, Airfoil Fans

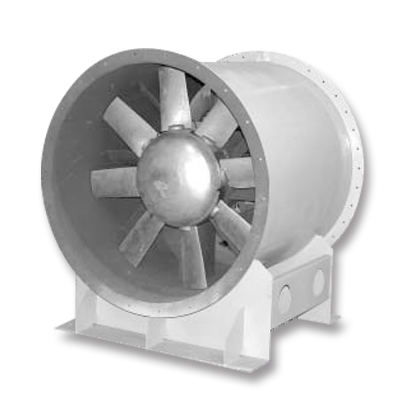

· Axial Fans: Propeller Fans, Tube-Axial Fans, Vane Axial Fans

| Centrifugal Fan | Centrifugal fans generate air volume and pressure by transporting air radially around the impeller and their characteristics vary depending on the shape and installation angle of the impeller blades. | |

|---|---|---|

| Multi-blade Fan | Multi-blade fans have wide width and short blade channels with impellers tilted forward relative to the direction of rotation and is also known as sirocco fans. Multi-blade fans operate at lower speeds than other types of fans and are primarily used when high air volumes are required at low pressures. Multi-blade fans operate over a wide air volume range of 30-80%, and their static pressure efficiency is typically highest at the highest static pressure, with a maximum static pressure efficiency of approximately 60-68%. Multi-blade fans are widely used in building air conditioning and ventilation applications due to low cost , wide operating range, and smaller impeller diameter compared to other centrifugal fans for the same air volume and pressure, which minimizes installation space. However, multi-blade fans are not suitable for transfer of materials due to their blade shape and structural weaknesses. | |

| Radial Fan | Radial fans are equipped with impellers with radial blades. As radial fans typically have narrower impeller widths than other fans, the impeller diameter becomes larger compared to a given capacity. This characteristic is a major factor in high manufacturing cost, and because impeller diameters are large relative to capacity, they are rarely used in air conditioning applications. Radial fans are suitable for transporting small volumes of air or materials at high pressures. In addition, they are surge-free and their shaft power increases linearly with air volume changes. Changes in shaft power significantly are helpful for fan control. | |

| Backward Curved Fan | Backward curved fans are centrifugal fans with blades titled backwards relative to the direction of rotation and operate about twice as fast as multi-blade fans, operate over a wide airflow range of 40-85%, and typically have a static efficiency of around 80%. Due to high efficiency, low overload resistance, and robust construction, backward curved fans are widely used in various applications, such as boiler air intake. | |

| Airfoil Fan | Airfoil fans, like backward curved fans, have blades titled backwards relative to the direction of rotation, but are equipped with an impeller with a blade cross-section shaped like an airfoil. Airfoil fans replace the blades of backward curved fans with airfoils. They have the highest static efficiency of any centrifugal blower, at about 86% and have low operating noise, so are widely used for clean air transport. | |

| Axial Flow Fans | Axial flow fans transfer air in the same direction as the impeller's axis, consist of propeller-type impellers with blade in airfoil shape. | |